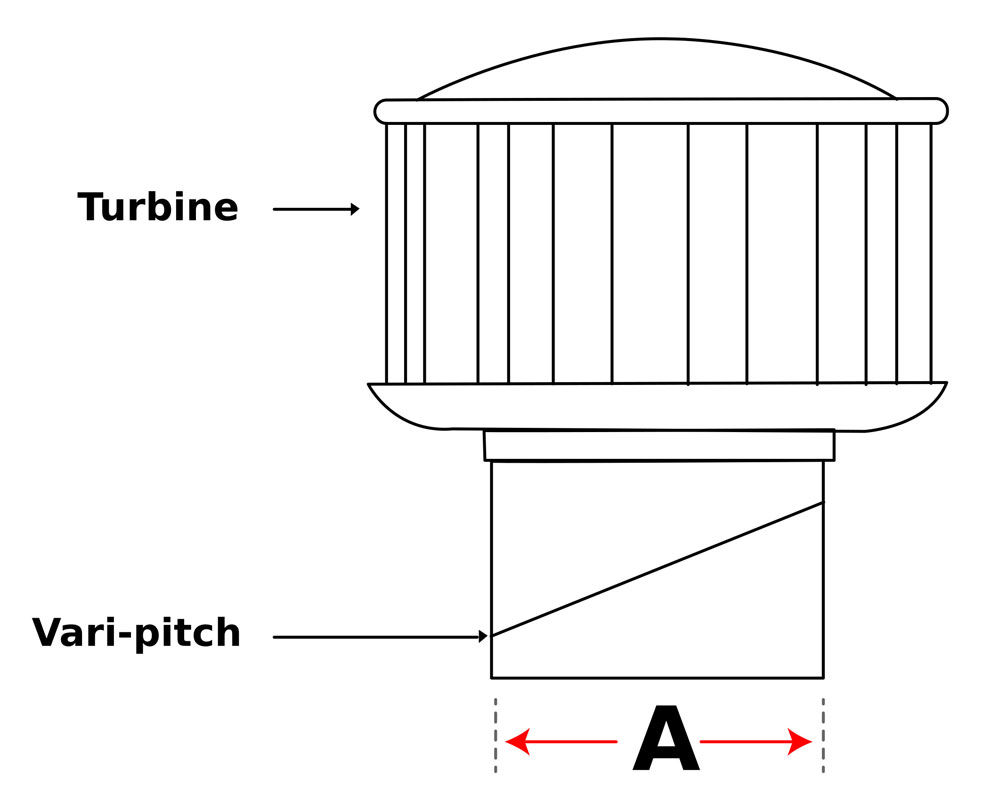

| Model | Dimensions – A (mm) |

| EP 400 | 400 |

| EP 600 | 600 |

| EP 900 | 900 |

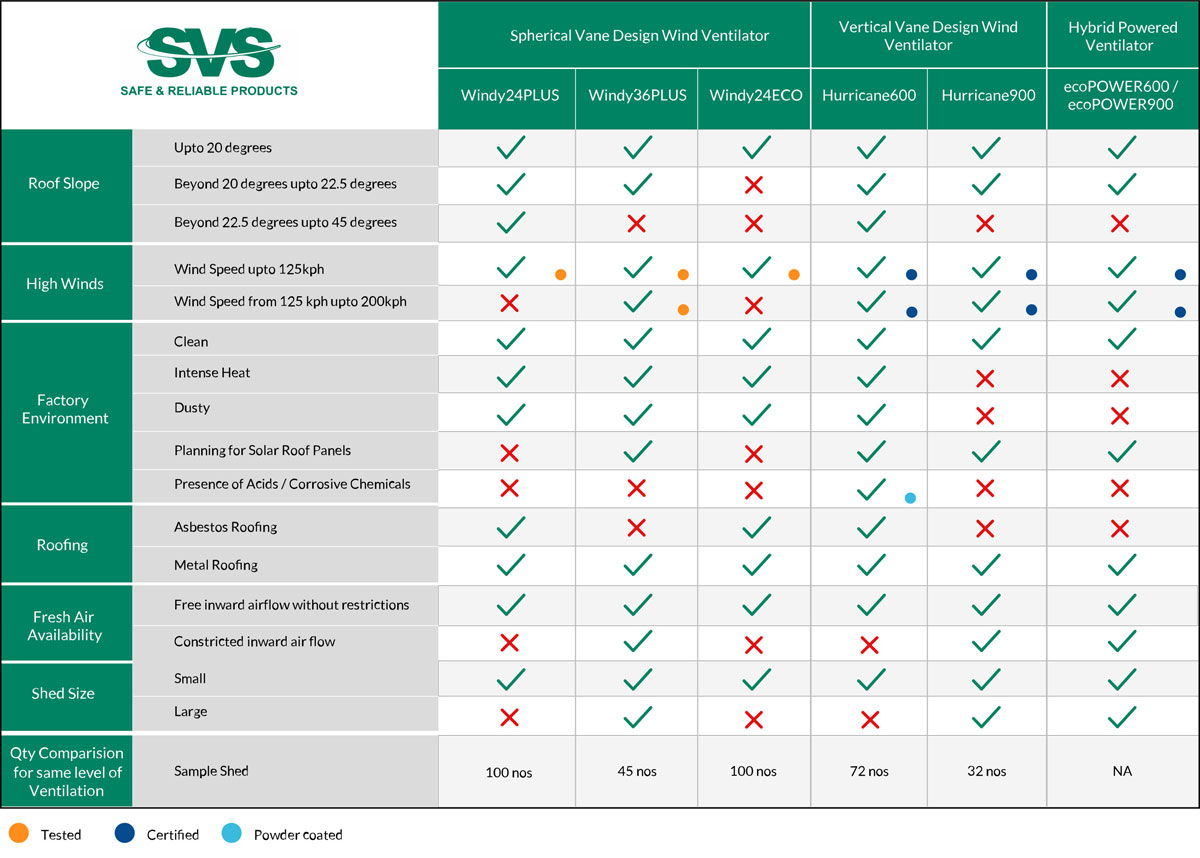

EcoPower

EcoPower pairs the leading design of Hurricane vertical vane ventilator with a high efficiency for reliable and on-demand peak performance, when required. Design patented in Australia

Weight

| Aspect | EcoPower 400 | EcoPower 600 | EcoPower 900 |

| Weight (kg) | 7.6 | 14.4 | 30 |

Electrical Specifications

| Feature | EcoPower 400 | EcoPower 600 | EcoPower 900 |

| Motor | Electronic Commutating (EC) motor | ||

| Input Voltage | 200 – 277 VAC 50 / 60 Hz | ||

| Max. running current draw | 0.55A | 0.71 A | 0.904 A |

| Max. running power consumption | 60 W | 99 W | 212 W |

| Specific flow rate (@ Δp=0) (kg) | 40.8 m3/hr/W | 44.0 m3/hr/W | 48.7 m3/hr/W |

| Sound Pressure Level LA (@3m & Δp=0) | 47 dB(A) | 36 dB(A) | 36 dB(A) |

Trusted by over 6,000 customers around the world

India’s largest ventilator manufacturer, installer, and exporter with more than 70% returning customers

India’s largest ventilator manufacturer, installer, and exporter with more than 70% returning customers